Once the design is finalized, we meticulously plan each phase of the execution process. This involves creating a detailed schedule that outlines key milestones, including demolition (if applicable), structural modifications, installations, and finishing work. Each step is scheduled to optimize efficiency and resource allocation, with an emphasis on minimizing downtime. Our project planning also includes contingency plans for unforeseen delays, allowing for adjustments while staying as close to the original timeline as possible.

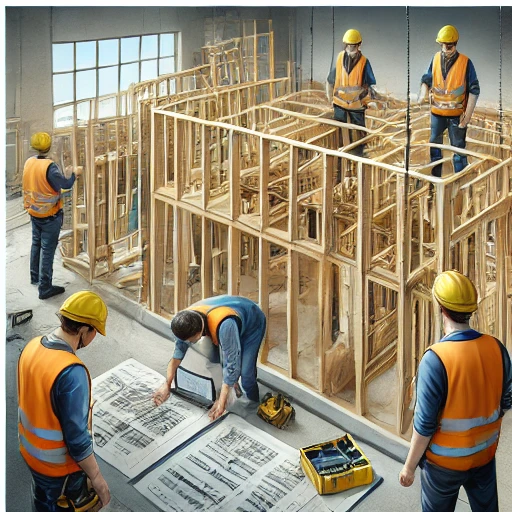

Skilled workmanship is the backbone of our execution process. We have a team of seasoned professionals, from carpenters to electricians, who are dedicated to upholding high standards. Each team member is trained to work precisely and safely, following design specifications to the letter. Quality control is integral at this stage, with team leads conducting inspections throughout the project to verify every aspect meets both aesthetic and structural standards, ensuring a flawless result.

A dedicated site supervisor oversees each project, ensuring that all work aligns with the design and is completed efficiently. The supervisor is responsible for maintaining a safe and organized work environment, troubleshooting on-site issues, and ensuring compliance with regulations. This role is essential for effective communication between teams and providing clients with updates. On-site supervision guarantees that the project progresses smoothly and according to plan, minimizing delays and ensuring quality.

Quality control is a continuous process in our execution phase. From initial groundwork to final touches, each step undergoes rigorous inspection to confirm it meets industry standards and client expectations. We evaluate everything from structural components to finishing details, checking for any imperfections or inconsistencies. By maintaining strict quality control, we guarantee that the final result not only looks great but is safe, durable, and constructed to the highest standards.